A BEGINNER

BUILDING THE QDX KIT

When the QRP-Labs website went live with the sale of the long awaited QDX, I was there, mouse in hand waiting to add one to the Shopping Cart, but to my amazement, the Cart told me that the product was Out Of Stock even though it had only just come online! I believe they had around 400 units and they all sold immediately. I was gutted!

To make matters worse, one of the chips on the PCB were no longer readily available, so QRP-Labs would have to try and source an alternative before they could get some more QDX's manufactured - and how long would that take?? Some people were saying that it could be months 😓

Two of my radio-club friends had been fortunate to have secured their purchase and it wasn't long before the kits dropped through their letterbox. In no time at all, one of them built his and had it up and running. The other guy decided he simply had too many things going on to build his kit - and sold it to me - hooray!!

I was so pleased about this because I really fancied not just the product, but the building of the kit too. I'd previously built a little Transistor Radio Kit by Tecsun and found it to be a great little weekend project. The idea of building something a bit more technical (not to mention more useful) was very appealing.

So I will use this post as a brief BUILD LOG. I'm not going to go into every detail because there's some excellent Video Logs on YouTube which are far more advanced than anything I could ever do. My take on things will be about how easy (or not) the kit is to build from a beginners point of view.

I'll highlight any hurdles and point out any pitfalls. I might even end up pointing out how everything went pear-shaped 😂😂😂. Fingers crossed it goes well.

_____________________________

The manual for the QRP-Labs QDX Kit is a staggering 105 pages long but only the first 37 pages are related to the actual build. Following that is a really good section guiding you into the actual operation of the QDX with software such as WSJT-X. The remainder of the manual goes into great detail about the design of the product, which was way over my head!

After checking the inventory to make sure you have all the parts available in the kit, the build is split into 14 sections and starts with the installation of the ceramic capacitors. Each part of the build looks quite straightforward but I must admit to being a little apprehensive about winding all those toroids for the Transformer, Inductors and Filters. Something I've never done!NOTE : THE FOLLOWING SECTION relating to 4 inductors no longer applies to new versions of the QDX!Looking around in the various forums and groups, I could see that quite a few people were having issues with failed output transistors and even the total death of the QDX. Reading between the lines, I could see that some of these failures might be attributed to the constructors choosing high input-voltage. Many people wanted the convenience of being able to use their standard 13.8V supplies and this results in a much higher power output than is recommended (potentially up to 8W), so I decided to go for the standard 9V input with up to 5W.

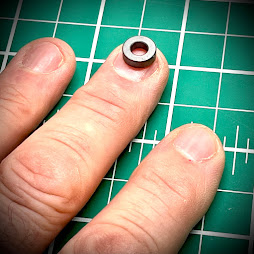

So, onto the kit. Well the first thing that smacks you in the face is the minute sizes involved! In the past I’ve built a small transistor radio kit and that was pretty compact, but the big difference here is the toroids - they’re absolutely tiny!!

|

| 5pence piece!! |

Anyway, I’m going to follow the Manual to the letter and that starts with fitting the Capacitors, followed by the Diodes, Transistors and then the TCXO board. After fitting anything I recommend ticking it off in the manual. Same goes for any testing that you're asked to do. Tick it off and you'll not miss anything.

With that done. it's time to do the T1 Transformer. I wasn't 100% confident with this but hopefully I've done it right 🙅

According to the manual, the next step is the Tapped Inductor L12,

BUT STOP FOR A MOMENT!!

If you are a beginner to all this kit-building and in particular, winding toroids, I would strongly advise you to hold back on the L12 for a few minutes and pre-build the other toroids, L14, L2, L3, L4, L6, L7 and L10.

Why?? Because these other toroids are super simple to wind and it will be good practise before starting L12, which has 3 loops in it (taps) and it's easy to get things wrong (like I initially did).

DO NOT INSTALL the other toroids, but just build them up ready for use later and be sure to mark them with a bit of masking tape before putting them aside.

You can see in the above example (L10) that this toroid has 13 turns as counted from the CENTRE. The "FIRST TURN" is the one on the right and it is counted anti-clockwise.

Okay, so now that you're much more comfortable winding toroids, you can start the bigger L12 feeling like you've got some experience behind you. The only difference here is that you will need to put three loops in at varying points in the winding process. I would recommend watching a video by someone called MISCDOTGEEK.

Remember to count your turns VERY VERY carefully! And remember too, that the loop goes BETWEEN the turn-numbers mentioned in the manual, so for example, as you have just completed turn 19, form a loop and then carry on with turn 20. The loop itself is not a turn!

Below is a simple example I've made up showing how a 6-TURN toroid with a Tap between 3 & 4 would look. Note how the winding starts on the left at the TOP of the toroid and ends at the bottom.

I'd like to give you a couple of tips... When you've wound the L12 Tapped Inductor and are feeling proud of yourself because you've checked it over and over and are 100% confident that it's perfect, just stop a minute and do yourself a BIG favour!

Get a Hot-Glue Gun and neatly fill the centre of the donut and give it a few minutes to cool. This will prevent the wire turns moving around as you wrestle with the toroid as you try to get all 5 termination points into the holes on the PCB. Without this, it is incredibly easy to get wires crossed over and out of alignment (I'm speaking from experience)!

It's still easy to get movement of wires on the outside of the toroid, but at least you don't have to worry about the inside wires. When you've finished the L12 Inductor, carry on following the manual - including the continuity tests on Pg.24.

The second tip is to forget the advice in the manual about burning off the enamel with your soldering iron or using the side-cutter method. No disrespect, but beginners are very likely to do some damage with either method in my opinion. It's better to scrape the enamel off with a sharp scalpel.

The next toroid to do is the T2 Trifilar which is super simple but you need to twist 3 lengths of wire together as one before doing the winding. The manual suggests using a couple of little screwdrivers to do the twisting but believe me, it's far easier to use a small, variable-speed drill. Put one end of the three wires into the drill-chuck and hold the other end of the wires taught with a pair of pliers and then SLOWLY rotate the drill. Make sure there's a nice neat row of twists and no kinks!

With all the toroids installed, I would suggest using the Hot Glue Gun to help keep them all in place. Without it, they'll be quite wobbly and prone to possible damage from knocks (even when in the case).UPDATE : Chris G4HYG replaced the tiny inductors and a few minutes ago I collected it from him. He had put the radio through its paces in his Lab and it was pushing out a solid 5W on all bands!

He also tested it in action on FT8 and reported that the 30M band sensitivity seemed slightly low but he still managed to make contacts as far away as Kazakhstan, so it's not that bad! He said it was a "Little DX machine". So my thanks to Chris for doing the SMD bits and the testing. He also tested the unit on 60M but that's a band I'm not allowed to use as an M7.

As a real measure of the QDX, I decided to connect it to my SotaBeams BandHopper which I'd temporarily installed in the back garden. It was setup in 40M mode which was just as well because I can only test during the evening times due to work commitments.

Although the BandHopper is supposedly resonant on 40M, the SWR is still slightly higher than I'd like down at 7.074MHz so I put the Elecraft T1 ATU inline to fine-tune the antenna and give the little transceiver an easy time.

I plan to try it on an indoor Magnetic Loop later and I'll have to pre-tune the loop using another radio (probably the IC-705) to make sure it's spot on before connecting the QDX to it.

To power the radio, I used a battery which I'd purchased specifically for the QDX. It's a 7.4V Lipo with a 5,000mAh rating. That should give me a good few hours use out in the field! For home use I've got a small mains 2A PSU putting out 9V. I was pleased to see that the PSU added no noise.

|

| 7.4V LIPO |

Setting up the QDX for WSJT-X was pretty straightforward and there's more than enough information in the User Manual to guide you through it if you've never used the software before. The only thing I don't like about this transceiver is that you can't reduce the power output - not even by using the Power-Slider in WSJT-X. That's a shame really, because I'd have liked to have the option to drop power right down into the mW range for experimenting with antennas and such like.

I've wrote a post on the QRP-Labs User Group to see if anyone can suggest why my receive signal seems down and hopefully they can make a suggestion as to why it may be so and how I can improve it.

Anyway, I'm just impressed that it even works! 😂😂😂

I'll update again later.

73, Tom, M7MCQ.

UPDATE : I reheated the solder points on L12 and the receive signals are now at normal levels but 30M remains slightly low. Nevertheless, contacts can still be made on that band (although I rarely use it to be honest). 20 & 40 are my favourite bands for FT8 👍

6 comments:

I was one of the lucky 400. The QDX needs a really good match to deliver the expected power. I have a 30m dipole and manual ATU with a good QRP power meter and despite the dipole being nearly perfect, the ATU was needed to get the QDX producing power. Once sorted, I've worked VK7 on 30m plus a couple of other closer VKs. Well on the way to QDX DXCC.

I'm impressed Tom, you did a fabulous job building this kit. Glad you could find a litle bit of help with the SMD parts. Reading your article I decided that this is not the kit for me to build. I ordered a simple QRM killer kit a while ago only to discover that I have to solder all the SMD parts which I can hardly see. Unfortunately I don't know anyone that can do it for me. So I think I will sell the kit and order one that is already in working order. Good luck using the QDX I hope you will have lots of fun with it. 73, Bas

Hi Mike,

Thanks for visiting the Blog - much appreciated. As you saw in the post, I used a good ATU but I don’t have a dedicated QRP Meter and don’t have any faith whatsoever in the regular meters. I looked all over for something decent but could only come up with the MFJ-813 which is now on its way to me.

73,Tom, M7MCQ.

Hi Bas, thank you for your kind comments. My eyes are 63 yrs old now, so there’s NO CHANCE of working with SMD LOL

Thanks for the visit. 73, Tom, M7MCQ

Good evening Tom, very much enjoyed the post and you did a great job on the build. There is always something to be said for building something and seeing it work. Be careful, the kit building can become addictive......before you know it you will be ordering a K2 from Elecraft?

Have a great week.

73,

Mike

VE9KK

Thanks for the visit Mike. I really enjoyed the build (apart from the Tapped Inductor which was a bit of a pain). I am certainly interested in doing more kits, but they'll have to be through-hole components - none of that silly SMD stuff, LOL.

73, Tom, M7MCQ.

Post a Comment