PART 1 - THE BUILD

I just love building kits, despite me having zero electronics knowledge. I'm not sure why these kits attract me so strongly - perhaps it's the creative side of me that longs to 'make something'. Maybe it's my inquisitive nature which always wants to peek and poke around to see how things work. Whatever it is, I am always excited when a new kit drops through my letterbox.Size wise, the Explorer is bigger than I thought - it measures approximately 6" x 4" with a decent 2-line LCD screen just under 3" wide. There’s only a single control on the front panel which, from an ergonomics point of view, is less than ideal. It has a decent built-in speaker.

The kit cost me £115 plus postage. I guess the closest radio to this that I already own is the (tr)uSDX which is also available in kit form (£70) and is also a 5W CW/SSB Transceiver, but the big difference between them is that the (tr)uSDX is a 5-band radio while the Explorer is only single band. The 'orange wonder' also has quite a few extra useful features which are lacking on the Explorer.

Maybe the Explorer's receiver is a far better performer than the (tr)uSDX - I don't know yet, but we'll soon find out I guess.

The kit itself arrives in lots of sealed bags, separating components and keeping things organised. There are probably over 800 solder-joints to be made in this full kit, so that's a lot of soldering!! Thankfully, there is no SMD work.

Just like I did with the QDX KIT and the QCX KIT (amongst others) I will post on here throughout the build process, showing warts and all. If I mess something up, I will declare it and I will tell you how I got around it (or how it all ended right there). If it ends up in smoke, then so what? There'll be no tears. This isn't a $2 Billion space shuttle!

This post is PART ONE which will show the build. PART TWO will be a separate post covering the testing and performance of the kit (as built by a clueless beginner 😂 )

First job was to print off the manual and in particular the PCB LAYOUT page, so that each component can be marked off as it's soldered to the board. This is a really handy thing to do and it slows you down, which is always a good thing!!

The first components to be installed are the ones from the bag marked "20M" and these include 1 resistor, 4 inductors, 11 capacitors and 8 crystals. None of these are polarised, so you can insert them any way around. My own pedantic nature forces me to insert the components in a particular way - eg all resistors are placed on the board in a manner that makes it easy to read their values - with the tolerance bands all to the right (or at the bottom if placed vertically). Having said that, I noticed later that I'd not fitted the yellow toroids all the same way 😡 I might desolder and turn it around😂

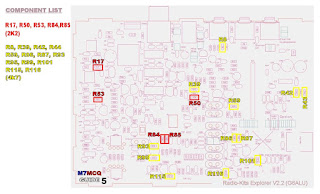

It very quickly becomes apparent that it can TAKE AGES to find things on the PCB because of how densely populated it is. Eg, I was searching for R93 for what seemed like forever. It wasn’t in an unusual place - I just couldn’t seem to see it! To help others quickly locate component locations, I’ve created some images (below) which will hopefully prove to be useful by showing you exactly where each component is located on the board to save you hunting around each time. I've grouped components together relevant to how they appear in the construction manual.I strongly advise that you buy a PCB HOLDER like the one below to make life easier for yourself. Good lighting and a magnifier really helps too. And don't go cheap on the soldering iron - you'll need a good quality iron for this kit - one which can maintain 350+ degrees with a nice, fine chisel-tip. All these resistors are the miniature-type and much smaller than you may be used to.

Populating the board with all the resistors, capacitors and diodes is long and laborious, so it's important not to rush through - it'll just end up in tears further down the line. Checking for correct component value, correct placement and good solder joints every single time is crucial - the key to success.

Just a word of warning about the diodes - make sure you get the orientation right because one bank of diodes is oriented the same way, while other banks alternate. It's easy to get it wrong if you're not focusing.

I used to insert a few components and then turn over the PCB and do the soldering, but it's not the best way for a beginner. Far better to insert a single component and then solder it and snip off the legs. It will take longer, but it's your best guarantee of getting it all right. Trust me!

Every time a wire goes through the core and back out, it is 1 turn. Just bear in mind that even though you are feeding through three wires at once, it still only counts as one turn each time you go through...

Once you've completed that task, get your multi-meter, and make sure that you have continuity between the wires on both sides...

14 comments:

Wow, Tom, you've been hard at work! Thanks for the write up of the construction...I'm very much looking forward to your follow-up posts.

73,

John

Thanks John! The receiver is working spot-on with no issues. There was a contest on this weekend, so a great opportunity to receive signals from across the globe!

TXing is different - I appear to have a problem where the PA BIAS menu option keeps resetting to its default low-level, which won't produce any power. I've written to RK and they're going to put together some test procedures for me to use. Hopefully, we'll get the issue sorted out and I'll detail it all in my next post.

Take care.

73, Tom.

Wow, Tom. What a great blogpost. Very detailed. Interesting kit to build. Not my piece of cake at the moment. But for someone that writes that he has no electronic knowledge you're doing extremely well. I'm shure you're starting to learn from it! Well done! 73, Bas

@BAS : Thanks very much Bas. I don’t seem to be learning much at all, LOL, but it’s all entertaining.

Hope you’re well.

73, Tom, M7MCQ.

Good morning Tom very nice attention to detail on the winding of the toroids and on T1-T5. Very nice pictures and explanations on how it's done. Very much enjoyed reading the post.

73,

Mike

VE9KK

@VE9KK : Thanks Mike. Hope it helps someone.

73, Tom, M7MCQ.

Hi Tom, it's G6ALU the designer! I purposely reset the bias every time you go in the menu so it's not accidently set high if replacing a transistor , I can change this though if there is demand.

@G6ALU : Hi Steve, thanks for popping by! It doesn't bother me that it resets every time - I just didn't know whether or not it should do :-)

There's a lot of interest in this new kit - I'll be taking it to a 'Show & Tell' at the radio club at some point soon. I suspect you'll get a few more orders.

Best regards,

Tom.

Hi, I read your blog with interest and my Radio-Kits Explorer kit arrived today. What have you used for a microphone? I can see from page 41 of the manual that the tip of the mike plug carries the audio and bias and the ring is PTT, presumably pull-down to talk. However, I wondered which mike you cannibalised or if you bought a two wire electret and a switch. Best regards, Robert M0NVQ

@ROBERT - Hi Robert, I used a TNT Microphone that I had in the shack - I think it's mentioned in PART 2 of the review (see below)...

https://tommcquiggan.blogspot.com/2024/03/radio-kits-explorer-part-2.html

@ROBERT - Again. If you look at my (tr)uSDX review and scroll down near the bottom of it, you'll see details of the TNT and also a RETAVIS that I played around with.

ALSO, take a look at the DAVE PEGLER mic which is aimed at KX3 users. It's a fabulous little thing costing around £20 and works VERY well with the KX3. Luckily, it uses a TRRS socket, allowing you to easily make up different leads without destroying it.

https://tommcquiggan.blogspot.com/2024/09/kx2kx3-ulra-light-mic.html

@Tom, I also spotted the "1-Pin Handheld Speaker Mic Microphone For Motorola Talkabout Radio Walkie Talkie" on the auction site. It has a 2.5mm sterio type plug with audio/bias to the tip and PTT on the ring. There is also an adapter from 2.5mm to 3.5mm for £2.60. Looks like I better get moving with the kit. Great BLOG by the way. I will take on board your BLOG details as I go. Best regards.

I’m currently building the Explorer and found the microphone and adapter hints very useful. Thanks. Peter

Hi Tom,

Just finished the build of my Explorer 20m. A joy to build and even more with your colorfull made component pictures. Took me a weekend and had no issues other than two twisted wires at T5. Yes the kit is a bit more expensive (also adding the taxes at Dutch customs) but very professional offered and i like to have some 'old school' suff in the modern shack again. Thanks again for your helpfull blog.

vy 73 de Johan, PA3ANG

Post a Comment